Packaging Maintenance Technician

Ninkasi Brewing Company · Full-time

Oct 2024 - Dec 2024 · 3 mos

Eugene, Oregon, United States

I’m an automation and equipment maintenance specialist focused on repairing and improving manufacturing machinery.

With over six years of hands-on experience and a two-year technical degree, I bring practical skills that will add measurable value to your company.

My projects section showcases over 100 pages of documentation, schematics, and CAD files, including an assembly with more than 700 parts. All projects are open-sourced under the MIT License for unrestricted use.

In my free time, I enjoy spending time outdoors and exploring technical projects in optics and astronomy.

Detailed Work History

Ninkasi Brewing Company · Full-time

Oct 2024 - Dec 2024 · 3 mos

Eugene, Oregon, United States

Tesla, Inc. · Full-time

Apr 2024 - Jun 2024 · 3 mos

Sparks, Nevada, United States

Responsible for repairing manufacturing equipment in Powertrain Manufacturing.

Applied technical skills to install, maintain and repair high-speed high-volume mechanical and electrical systems, factory automation and robotics.

Work History:

Apr—Jun 2021 • 3 mos

Model 3/Y Battery Pack, Enclosure Weld

HP, Inc. (Kforce, Inc. Contractor) · Full-time

Aug 2023 - Dec 2023 · 5 mos

Corvallis, Oregon, United States

Repairing industrial automated systems.

My Completed Education

Linn-Benton Community College

Sep 2016 - Jun 2018 · 1 yr 10 mos

Albany, Oregon, United States

Grade: 3.94/4.00

Accreditation: Northwest Commission on Colleges and Universities

Learned the fundamentals of Programmable Logic Controllers, industrial maintenance, electrical troubleshooting, hydraulic/pneumatic assembly and testing, process-control/instrumentation, and electromechanical assembly and testing. Covered low and high voltage electrical systems.

Capstone project: Two wafer handling robot arms (donated by HP Inc.) were integrated into a production line scenario utilizing two Arduino UNO's and an Allen-Bradley ControlLogix 5000 Series PLC. Required C++ and Ladder Logic program design, electrical prototyping and testing, and some circuit analysis.

Electives:

Electrical and Mechanical Projects

Open Source Project

Status: Early Design Phase

A fully open-source, open-hardware telescope project which is currently in the early design phase. First milestone is testing a scaled down model to verify the optical system is feasible. Please follow this link to see the intended design, it's my ray-trace example of 0.4 meter binoculars.

Basic principle is: Concave primary mirror, concave secondary mirror, and a Nasmyth style tertiary flat mirror. With a fast focal ratio primary mirror, sub-f/3.0, it allows for minimal obstruction of the light path, plus combining that with a Gregorian secondary mirror in a binocular format allows for the upright image to be displayed for the user at the back end of the telescope. So no matter the size of the binoculars, the user will see a bright up-right image with both eyes open, just like a small hand-held pair of binoculars.

Links for more information:

3d-cad.stp (Currently a very work-in-progress)

documentation.pdf (Currently a work-in-progress)

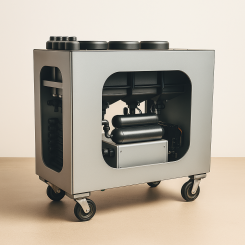

Open Source Project

Status: Assembly & Testing Phase

A fully open-source, open-hardware project with the slated goal of becoming a UL-compliant device for automated gravity-fed dosing. Applications for this project include; nutrient dosing for a hydropnics/aquaponics, continuous culture feeding in bioreactors or fermenters, microfluidic experiments, controlled reagent delivery, and wastewater chemical treatment.

Project is currently in a build-out and long term testing phase. The goal with this phase is placing various components under stressful environmental conditions in order to improve reliability. Since this project incorporates hundreds of components, and I did all the design, building, and testing myself, there is a high probability of individual component failure. Isolating these failures now is main intended goal of this phase.

Links for more information:

3d-cad.stp (Contains 700+ parts in main assembly)

electrical.pdf (Machine-tool grade wiring schematic)

mechanical.pdf (coming soon)

Academic Project

Status: Completed

Operation of the machine is for rejecting short-width bearings and accepting a tall-width bearings. The tall bearing would then be picked up and placed into a bearing housing on a conveyor line. The system uses 5 electrically actuated directional control valves to power 5 pneumatic cylinders and requires 12 sensors for operation.

Links for more information: